MIAMI – KSF Space announced on Friday, January 9, 2026, the commercial availability of an expanded lineup of CubeSat structures, positioning the series as the most affordable solution currently on the global market. The new offerings include 1U, 2U, and 3U form factors specifically engineered to reduce financial barriers for university researchers and emerging national space programs.

The launch follows the company’s previous efforts to lower orbital access costs, including the development of the Jupiter Rocket suborbital testing platform and their Flexible CubeSat Kit 2.0.

Material Properties: PA11 vs. Aluminum 6061-T6

A central feature of the release is the option for mission prime contractors to choose between industrial-grade polymer and traditional aerospace metals. The polymer structures utilize PA11 processed through industrial HP Multi Jet Fusion (MJF) technology.

Technical specifications for the PA11 variants include:

- Mass Efficiency: PA11 provides an approximate 40% mass reduction compared to aluminum, allowing for increased battery density or payload capacity.

- Impact Resilience: The ductility of PA11 facilitates improved absorption of mechanical shocks and high-frequency vibrations during launch vehicle separation.

- Vacuum Stability: Verified Total Mass Loss (TML) of less than 1.0%, meeting requirements to protect sensitive optical sensors from molecular contamination.

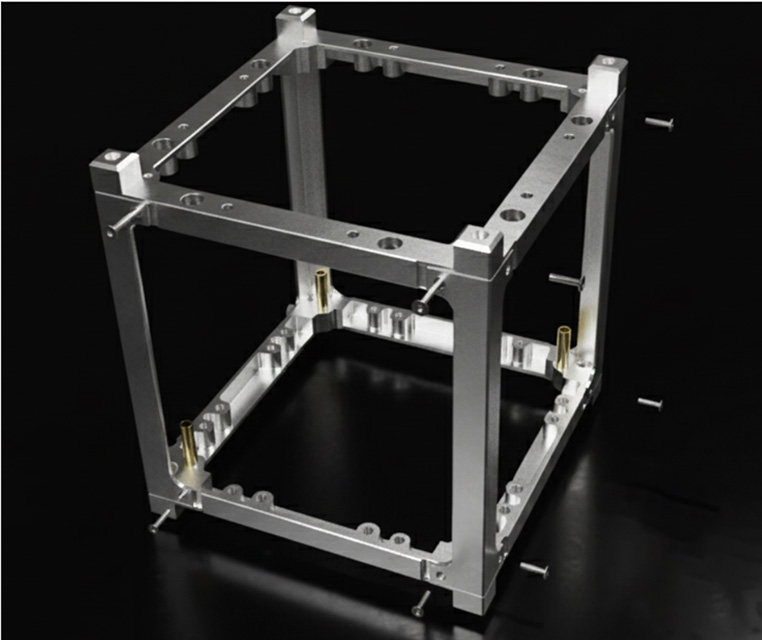

For high-power missions, KSF Space continues to provide CNC-machined Aluminum 6061-T6/7075 structures. These metallic frames function as superior heat sinks for high-power transmitters and feature hard-anodized rails to prevent cold welding during deployment in Low Earth Orbit (LEO).

Verification and Engineering Standards

Every unit is developed and verified under the NASA-GSFC-STD-7000 (GEVS) framework. KSF Space utilizes SOLIDWORKS Flow Simulation and Finite Element Analysis (FEA) to ensure structural integrity at Max-Q (maximum dynamic pressure). The structures are designed to maintain a ±10°C thermal margin relative to predicted orbital temperatures, protecting internal avionics throughout the mission lifecycle.

[Image showing a Finite Element Analysis (FEA) thermal map of a CubeSat structure during orbital simulation]

Mission Readiness and Integration

“Our goal has always been to democratize space,” said Dr. Mohamed ElKayyali, Chairman of KSF Space. “By providing a CubeSat structure that is both affordable and technically rigorous, we are enabling the next generation of researchers to move from conceptual design to orbital reality faster.”

The structures are compatible with the PC/104 mounting standard and are available in two tiers: Educational Models for lab prototyping and Professional Flight Models, which are delivered clean-room ready with full flight qualification. KSF Space also offers these structures bundled with its NEP Certification program to support the training of university-level satellite engineers.

2026 Mission Timeline

The PA11 structures are currently available with a lead time of one to two weeks, while custom aluminum frames are shipping on a four-to-six-week cycle. KSF Space is now accepting technical quotes for 2026 mission integration.