Palm oil, the world’s most widely consumed vegetable oil, is an inescapable component of most manufactured consumer products, present in roughly 50% of supermarket packaged products ranging from pizza to toothpaste, or products like animal feed and biofuels.

Grown primarily near the equator, palm oil production is incredibly efficient, with the highest yield per hectare among vegetable oils, but still has traditionally been known for its deforestation impacts, as rainforest in tropical areas has been cleared to make way for plantations.

While the deforestation impacts are widely known, satellites are now also beginning to uncover a previously unseen impact of palm oil production: methane emissions.

Following the publication of a scientific study in Environmental Research Letters, which confirmed the accuracy of GHGSat’s high-resolution satellites in measuring methane from palm oil mills, GHGSat’s constellation has increasingly homed in on palm oil ponds in tropical regions around the world, including South America, Asia, and Africa. As of late April 2025, GHGSat’s fleet of satellites has identified more than 50 methane emissions from 12 different countries.

Methane from palm oil mills is not unexpected, as it stems from the industry’s standard production processes and byproducts. Palm oil production produces a large amount of wastewater, known as POME (palm oil mill effluent), which is typically stored in open ponds. As the organic waste in the ponds, such as pulp and shells from the palm fruits, decomposes, it produces methane in a process much like decomposing trash in a landfill. The pond system was designed to curb local water contamination from releasing POME into the riverways and channels, but had an unintended impact. Now, however, for the first time it can be accurately quantified by satellites.

Now, the ability of satellites to quantify the methane from palm oil mills paves the way for potential better accounting of the industry’s total environmental impacts and effective, profitable mitigation of the emissions.

Landfill operators and municipalities with similar methane challenges have seized on the potential of waste diversion, recycling, or and gas capture systems to limit methane emissions or even transform them into a source of additional profit—converting it to natural gas to sell back to local power grids or power on-site operations. Similar approaches and technologies exist for palm oil mill operators.

The Roundtable on Sustainable Palm Oil (RSPO) was formed in 2004, and sets sustainability standards for the palm oil sector, certifying growers that meet those standards. Alongside other initiatives related to deforestation and workers’ rights, RSPO has developed a PalmGHG calculator to enable palm oil growers to estimate their net greenhouse gas emissions and implement more sustainable practices.

Palm oil is a $48.1 billion industry, concentrated in countries near the equator, with Indonesia and Malaysia estimated to produce roughly 90% of the global supply. The Roundtable for Sustainable Palm Oil estimates that the industry provides a living for some seven million smallholder farmers globally, including direct jobs for four million people in Indonesia and nearly a million in Malaysia. Many of the economic benefits of palm oil are focused in remote, rural areas where work can be hard to find.

This is the power of high-resolution satellite technology: it illuminates a previously opaque challenge, and delivers the insights required to map out a solution,” said Stephane Germain, CEO of GHGSat. “Precise data is the first step toward action, and satellite technologies are a part of the puzzle.”

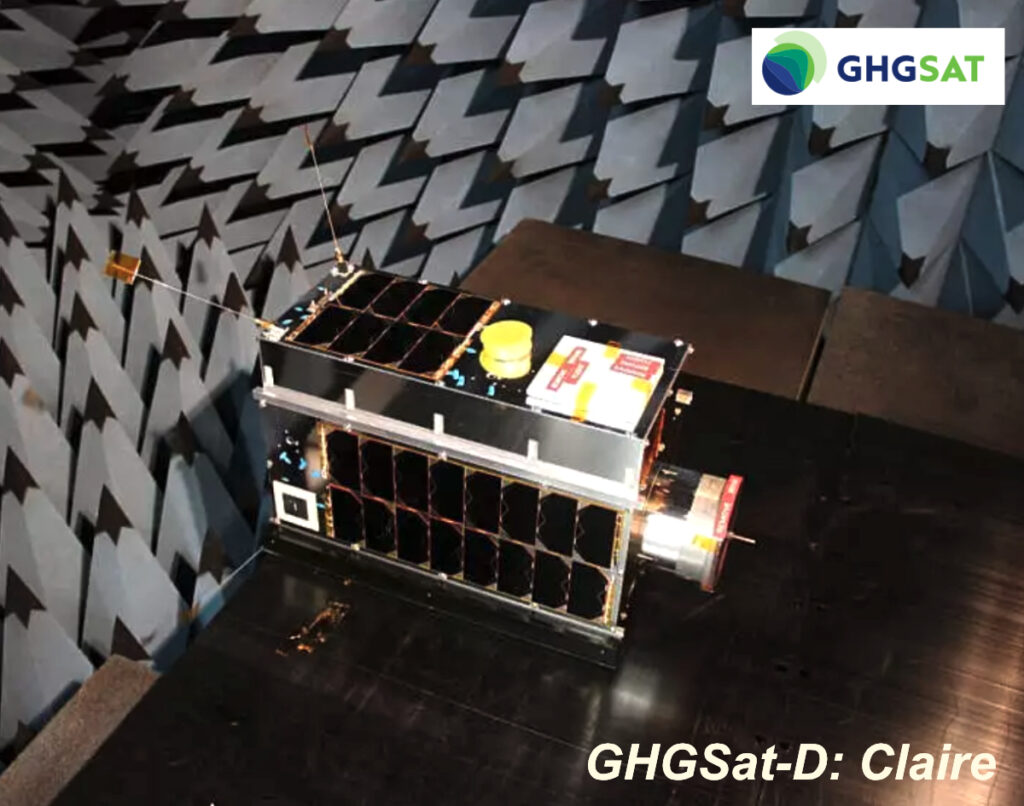

As industries worldwide, from the energy sector to mining or palm oil, seek to mitigate emissions from their activities, GHGSat serves as a trusted partner, providing independent data to global industry and government leaders so that they can tackle emissions with confidence. GHGSat made history in 2016 with the launch of the world’s first satellite capable of directly attributing methane emissions to individual industrial facilities. Since then, the company has steadily expanded its proprietary constellation, which currently includes 12 commercial satellites in orbit, which track emissions from tens of thousands of sites per day—a number far exceeding the capacity of any emerging competitor. GHGSat’s expanding fleet continues to set the standard in satellite emissions monitoring, enabling faster response times and greater coverage than any other player in the market.