The Giant Magellan Telescope and Ingersoll Machine Tools Inc. have started the manufacturing and assembly of the largest telescope mount built in the United States.

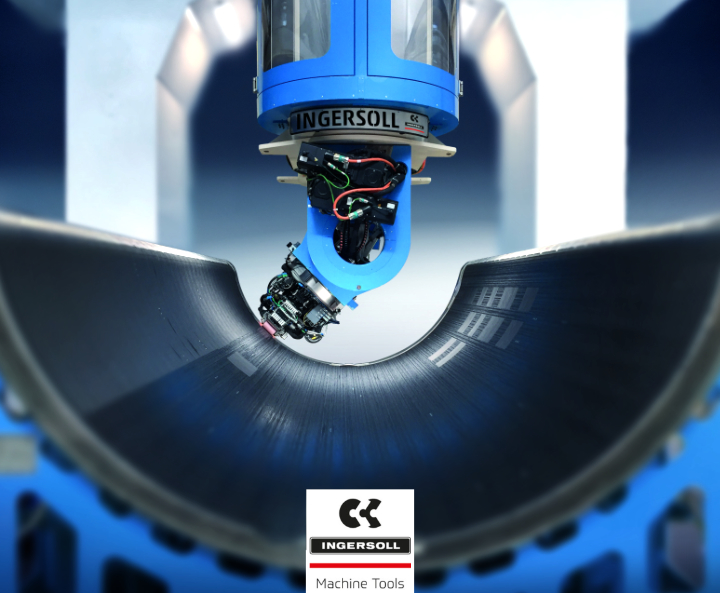

The 39-meter-tall precision moving structure was developed in partnership with OHB Digital Connect. In 2022, Ingersoll finalized its 40,000-square-foot manufacturing facility expansion, equipping it with the nation’s newest and largest gantry mill to construct the mount. Once assembled, the mount will undergo performance testing before being shipped nearly 6,000 miles to the Giant Magellan Telescope site in Chile for reassembly.

The Giant Magellan Telescope mount weighs 2,100 metric tons and is designed to support seven of the world’s largest mirrors, adaptive optics, and scientific instruments. Despite its immense size, the mount is remarkably agile, gliding frictionlessly on a film of oil just 50 microns thick, resisting image quality disruptions and allowing it to track celestial objects billions of light years away. The steel structure sits atop a 22-meter-diameter concrete pier that was engineered to protect the telescope during seismic events in the Chilean Atacama Desert.

Producing the mount with such precision involves a large workforce of skilled engineers, designers, and manufacturing professionals across multiple states. Industry leaders and policymakers recently gathered in Rockford, Illinois, part of America’s manufacturing heartland, to tour the new Ingersoll facilities where the mount will be assembled over the next 6 years using steel sourced from the United States.

The Giant Magellan Telescope will be 200 times more powerful than today’s best telescopes. This power stems not just from its large 25.4-meter diameter primary mirror array, but also from the synergistic performance of its efficient optical design and advanced scientific instruments. The innovative design makes the Giant Magellan Telescope unique among the new class of “extremely large telescopes” for its ability to deliver the highest performing combination of image quality, field of view, and light sensitivity ever achieved.

Advancement of mount fabrication marks a major milestone for the Giant Magellan Telescope, now 40% under construction across 36 states and on track to be operational in Chile by the early 2030s.

“We are proud to be a part of developing and building the mount structure for the Giant Magellan Telescope. Ingersoll’s rich history of building very large, complex, and very accurate machine tools complements the unique design of the telescope and the impressive engineering capability of our partner company OHB in Germany,” said Jeffrey Kimberly, Chief Operating Officer of Ingersoll Machine Tools. “The collective expertise of this entire team is what makes it possible to build this impressive scientific wonder that will lead to new discoveries that are beyond our imagination with today’s current capabilities.”

“Our cost-effective design enables us to build the Giant Magellan Telescope faster and with less risk, all while achieving the broadest range of scientific capabilities,” said Robert Shelton, President of the Giant Magellan Telescope. “Ingersoll’s global experience in manufacturing giant precision structures has been instrumental on our way to becoming one of the most powerful ground-based telescopes in the world.”

About Ingersoll Machine Tools

Founded in 1891, since 2003 Ingersoll Machine Tools is part of the Italian holding Camozzi Group, an international player specializing in the engineering and production of high-tech components and solutions for industrial automation. The Group also designs and manufactures intelligent cyber-physical systems, leveraging its longstanding expertise in mechatronics. Additionally, it produces high-tech textile machines, special machine tools and develops advanced solutions for additive manufacturing dedicated to the aerospace, naval, and energy industries. Since its inception, Ingersoll Machine Tools Inc. has been an iconic name in the milling machines sector, successfully serving the defense and then the newborn aeronautics/aerospace industry. During the 1990s Ingersoll pioneered the automatic fiber placement and the automatic tape laying technologies for composite manufacturing and became one of the leaders for this market. Since 2015, the expertise, methodologies, and techniques acquired in developing composite manufacturing have served as an extraordinary technological springboard that allowed Ingersoll to enter the additive manufacturing sector and to immediately diversify from the competition with its offer of wide-and-high 3D printers (MasterPrint®) that completes and complements its composite and subtractive products portfolio.

About Giant Magellan Telescope

The Giant Magellan Telescope is the future of space exploration from Earth. Using seven of the world’s largest mirrors, the 25.4-meter telescope will produce the most detailed images ever taken of our Universe. It will uncover the cosmic mysteries of dark matter, investigate the origins of the chemical elements, and search for signs of life on distant planets. The Giant Magellan Telescope is the work of the GMTO Corporation, a 501(c)(3) nonprofit and international consortium of 14 universities and research institutions from the United States, Australia, Brazil, Chile, Israel, South Korea, and Taiwan. The telescope is being built in America and will be reassembled and completed in Chile by the early 2030s.