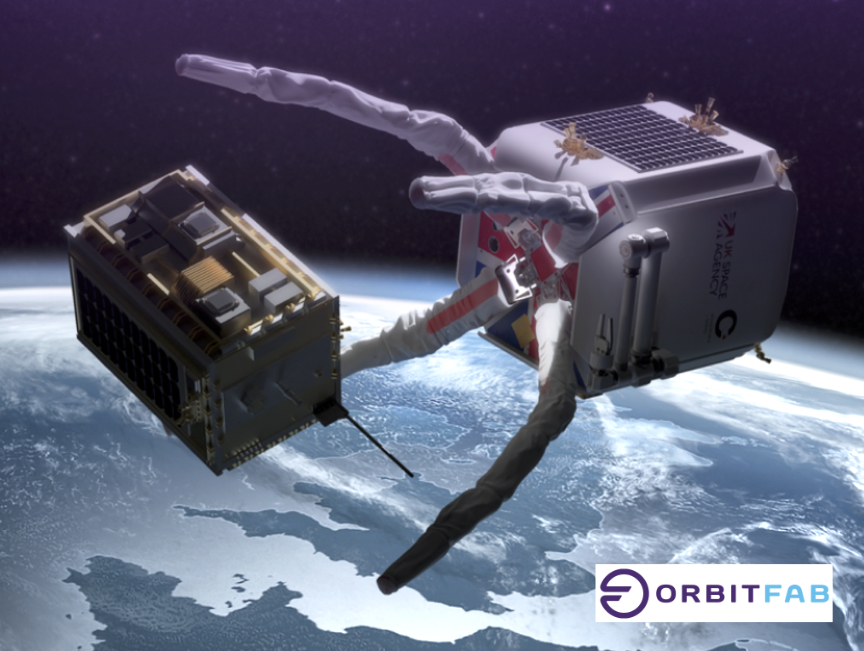

Orbit Fab has completed the testing of its refueling payload and testing of the GRIP™ capture and active in-space refueling nozzle with automated docking, which eliminates the need for complex robotic arms for refueling.

Image is courtesy of Orbit Fab.

After completing rigorous GRIP testing and in-space refueling simulations, Orbit Fab has successfully retired major technical risks ahead of key government and commercial in-space servicing missions beginning next year.

Numerous hardware tests of Orbit Fab’s GRIP capture mechanism and refueling interface were conducted by the company’s engineering team and government customer representatives, using the

Air Force Research Lab’s (AFRL’s) state-of-the-art simulation facilities at Kirtland Air Force Base in Albuquerque, New Mexico.

A hardware testbed of a fuel shuttle, equipped with an Orbit Fab GRIP refueling mechanism, simulated the replenishment of a satellite low on fuel and featuring a RAFTI™ (Rapidly Attachable Fluid Transfer Interface) refueling port. Engineers tested a broad range of the GRIP mechanism’s capabilities, which exceeded all requirements as the fueling device approached the satellite from different angles and velocities, and as it docked with, locked on, and pushed off from the model satellite equipped with the refueling port.

The successful GRIP tests mark a major readiness milestone toward upcoming in-space-refueling and servicing missions. Orbit Fab delivered GRIP hardware this month, as well as a number of RAFTI units, ahead of multiple refueling missions that will use Orbit Fab’s GRIP and RAFTI interfaces.

The Space Force Tetra-5 program satellites will be among the first to have Orbit Fab’s RAFTI refueling ports during a first-of-its-kind refueling operation next year. An Orbit Fab fuel depot featuring its GRIP active docking and fluid transfer mechanism will lock on to the satellite’s RAFTI refueling port, create a fluid connection, and securely replenish each satellite.

Orbit Fab is partnering with a broad range of companies to produce fuel shuttles, which will feature GRIP refueling interfaces and fluid transfer systems. The Space Force Tetra-5 refueling mission in GEO is just one of many named and yet-to-be-named commercial and government programs that have selected Orbit Fab’s RAFTI and GRIP for spacecraft ground and on-orbit fueling operations. The DoD’s Defense Innovation Unit (DIU) has contracted with Orbit Fab for the first in-space fuel sale in GEO and has selected Orbit Fab’s RAFTI refueling port and GRIP docking and refueling nozzle as part of its RAPIDS Refueling and Fuel Depot Initiative.

“These successful performance tests of our GRIP active in-space nozzle and automated docking device mark a major accomplishment and milestone for our customers’ upcoming missions. The overall space economy is able to use GRIP and RAFTI refueling interfaces to redefine dynamic space operations,” said Daniel Faber, Orbit Fab CEO. “We are ahead of schedule following these key GRIP tests that put the major technical risks behind us. We will be providing GRIP and related fluid transfer systems to multiple partners who wish to add fuel delivery capability to their satellite servicing vehicles.”

“Orbit Fab’s GRIP tests and RAFTI qualification milestones show the care that our engineering team has for our refueling customers. Refueling allows a spacecraft to be agile and flexible during operations and adds mobility options for the satellite operator,” said Adam Harris, Orbit Fab’s Chief Commercial Officer. “RAFTI refueling ports are flight qualified and for $30,000 can replace a spacecraft fill and drain valve while adding the flexibility for in-space refueling. Orbit Fab is providing commercial and government missions a viable, affordable path to in-space refueling for spacecraft being built today.”

Orbit Fab is in discussions with space industry manufacturers to build RAFTI, under licensing agreements aimed at meeting growing demand for in-space refueling. The licensing agreements will initially accelerate RAFTI production and delivery to meet commercial and government market demand, while Orbit Fab focuses on propellant sales and GRIP production for in-space fuel delivery shuttles.