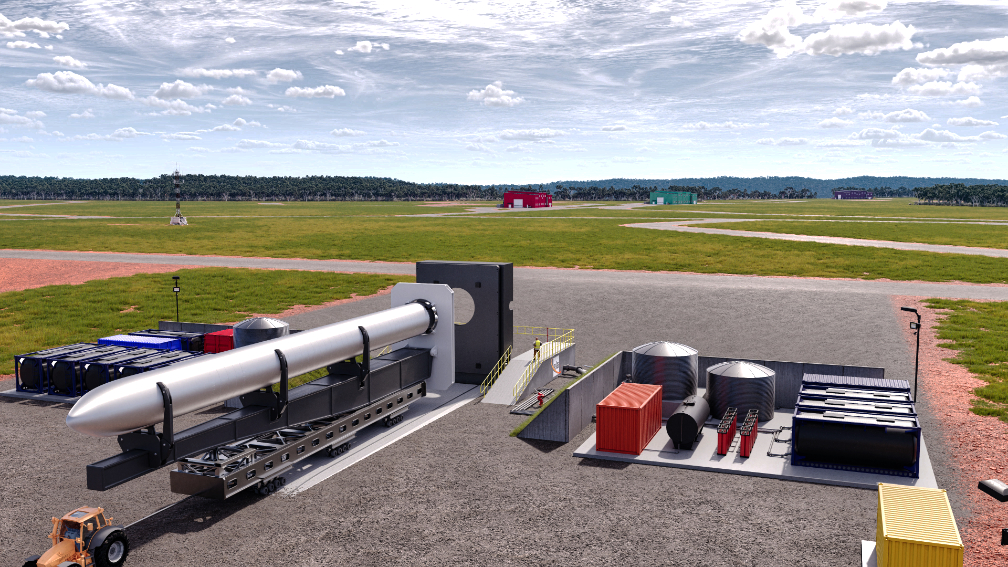

Equatorial Launch Australia (ELA) has released completed designs for the company’s state-of-the-art launch pads – a world first in launch pad design that allows any NewSpace rocket to be quickly and seamlessly mated with the pivot base of the pad and that enables all seven Space Launch Complexes (SLCs) at the Arnhem Space Centre (ASC) to launch any rocket with little notice for configuration change.

The company believes this innovative design is the most advanced New Space small to medium rocket launch pad in the world and will help to meet rapid-responsive launch needs in the future. The design also significantly minimizes damage created by rocket plumes, substantially increasing the reusability of the launch pads.

The highly technically advanced design, named the Arnhem Space Centre Advanced Launch Pad (ASCALP), will accommodate all current class NewSpace small launcher rockets up to approximately 450,000 kg launch weight (up to 3000 kg payload weight). The pads will provide advanced thermal and acoustic protection damage mitigation aspects, advanced environmental and safety aspects as well as detailed and comprehensive support services integration. The pads were also designed with the aim of simplifying and making rocket handling, mounting and support safer and more efficient.

ELA has designed the ASCALP as a fully integrated and all-inclusive pad which incorporates extensive, safety, flexibility and efficiency of support services such as gases, propellants, oxidizers, and data acquisition and transmission that are required for launch.

The key features of the ASCALP design include: A 90-degree, triple redundancy, hydraulically controlled Pivot Base which facilitates easy and quick rocket mount and dismount, a detailed support service layout with permanent plumbing, control manifolds, and digital control and monitoring of all gases and liquids. The pads and pivot bases at every SLC are the same and are pre-designed to accommodate either single barrel, dual booster and quad booster rockets.

Each rocket has its own custom designed Interface Plate element that allows for easy connection to the Pivot Base and doubles as the work platform. All rocket services and the umbilical connection are integrated and routed through the Pivot Base to the interface plate and on to the rocket itself. This design allows each pad to accept the wide range of rocket sizes and shapes and their attendant support equipment including strong back variations, hold down/retention device mechanisms, umbilical configurations, and other support services and devices.

The pad also incorporates an advanced 80,000 liter Water Deluge System via either an annular or rectangular outflow manifold which is aimed at reducing the potential adverse thermal and acoustic effects on both the rocket and pad of up to 16500km/h high velocity and >4000°C rocket plume. Extensive research and testing with unique computational fluid dynamic analysis of the proprietary manifold design with various flow aperture sizes and locations optimizes the spray/flow pattern effectiveness.

A multi-layer/composite plume deflector is a key element of the ASCALP design. The multi-angular deflection and channeling/containment device uses steel, heat resistant concrete and proprietary ablative coating to minimize the damage created by the plume, allowing multiple launches without refurbishment or replacement.

The 12 meter (standard) height of the pad – from rocket base to bottom of plume deflector and plume chamber is a key element in the management and mitigation of both thermal and acoustic risks and currently unique for smaller NewSpace rocket pads.

The use of a large volume Environmental Capture Pond, or colloquially named “Baby’s Bath” with filter and return pumps is incorporated on every pad and is essential to capture and filter any residue from the launch and reuse any deluge water as part of the extensive layered environmental protection plan used at the ASC.

A nitrogen based ‘Oxygen Purge System’ for fire control following a launch abort. This system automatically floods the area at the base of the rocket with nitrogen to purge oxygen and help reduce the risk of ‘slow rate’ fire. The provision of four automated and steerable fire cannons at the base of the pad area also assists in fire control and safety. The water for these cannons and the separate deluge reserves are from collected and stored rainwater.

Rocket Trolley

As a purpose-made, complimentary design to the advance launch pad, ELA will also soon complete and release the final design of its advanced Rocket Trolley. The Rocket Trolley is being designed to carry rockets up to 45 meters in length and up to 130,000 kg in total mass (with strongback, base and Interface Plate connected) from the Horizontal Integration Facility (HIF) at each Space Launch Complex (SLC) of the ASC to the launch pad. Most empty rockets in the small, medium range weigh less than 20 tonnes empty, however, multi booster solid fuel rockets can weight up to 100 tonnes.

The Rocket Trolley allows the rocket to be easily mated horizontally with the 90-degree Pivot Base and has been design to hydraulically adjust the lateral and vertical position for precision loading and attachment of the Interface Plate with strong back attached to the Pivot Base of the pad.

A Complete Integrated Launch Pad Solution

The ASCALP was designed from the outset to be a comprehensive launch solution which allowed integration with each customer and to provide efficiency and cost-effective solution.

Every customer at the ASC will use the ASCALP and in some cases additional elements of the clients launch system will be incorporated into the base ASCALP design.

“Every element of this ASCALP is designed to improve the safety and efficiency of launch. It is also designed to make the operation of the Arnhem Space Centre much more efficient and cost-effective. The use of a proprietary Interface Plate element seamlessly mating a rocket to the Pivot Base of the pad allows each rocket to mate and be used with the standard launch pads anywhere on the ASC site” said . “This has multiple advantages, including having all seven Space Launch Complexes at the ASC able to launch any rocket with very little notice for configuration change. The use of a standard Pivot Base and adaptable Interface Plate allows the pad to be quickly adapted and changed for another rocket if necessary. Eventually every rocket company customer will have their own Space Launch Complex at the ASC, but this plan allows us maximum flexibility as we grow into that situation. The design and re-usability of the deflector and the lack of damage to the pad overall was a key aim and it all adds to the efficiency and cost-effective solution we are offering our customers,” — Michael Jones, Chairman and Group CEO, Equatorial Launch Australia

Jones continued, “This 12m height and the design overall are made possible due to the positioning of the majority of pads at the ASC being as close to the edge of the escarpment upon which the spaceport is located as possible. Pushing the pads to these edges allows us to get the maximum safety spread of multiple pads as well as using the natural topography of the spaceport’s location, for the pad’s essential and unique technical requirements. Due to the heat and type of propellants used by modern rockets, the residue/effluent from launches is incredibly small, and when considering the number of launches from the ASC across a year the facility’s contribution to longer-term average concentrations of air pollutants will be negligible, nevertheless, we take this very seriously. We have been collecting water, soil and air samples over an expanded local area for more than two years now and will continue this monitoring and control process into the future. We are really proud of this pad design and in some ways, it is the center piece of our commercial offering at the Arnhem Space Centre. Our in-house space technology and engineering team took my design concept and the user requirements which we have gathered over several years and have completed the design, analysis, construction, manufacturing plan and come up with a completed comprehensive design which we are really proud to release to the market. This is a game changer in the NewSpace launch market.””

“When we first introduced the ASCALP design to our customers we received some push-back – not every customer was at the same stage and had fully scoped their launch system. Others did, and so we had to do some work to convince them of the benefits and the need for both increased safety and also efficiency. We think we have achieved a pretty good situation now. At the end of the day, they are the customer, and the customer is always right, but our engineering systems and Launch Facility Licencing requirements dictate we have a very strong view of the integrated launch systems and a desire for commonality where practical, and this all translates to all things related to the launch process, so we have been, and still are, getting very involved with our clients launch engineering and mission plans. Our contract 100% supports this with a very detailed division and determination of responsibilities, and requirements for operating at the ASC,” concluded Mr Jones.