UPDATE #2: “We have liftoff,” as Starship returned to integrated flight testing with it’s second launch from Starbase in Texas. While it didn’t happen in a lab or on a test stand, it was absolutely a test. What we did will provide invaluable data to continue rapidly developing Starship.

During this morning’s preparation to the launch the on air hosts at SpaceX informed us that helpful data learned after the first launch resulted in modifications such as design changes and ultimately hardware changes. The delay yesterday was to replace a grid fin actuator on the launch stack, and then it was decided to also replace two other actuators as a precaution.

Starship successfully lifted off under the power of all 33 Raptor engines on the Super Heavy Booster and made it through a successful stage separation. The booster experienced a rapid unscheduled disassembly after stage separation and boostback burn while Starship’s engines fired for several minutes on its way to space.

With a test like this, success comes from what we learn, and today’s test will help us improve Starship’s reliability as SpaceX seeks to make life multiplanetary.

“Starship successfully lifted off under the power of all 33 Raptor engines on the Super Heavy Booster and made it through a successful stage separation.”

We’ll continue to share updates here as the team reviews data from today’s test. Thank you to our customers, Cameron County, and the wider community for the continued support and encouragement. And congratulations to the entire SpaceX team on an exciting second flight test of Starship!

UPDATE #1: The second flight test of a fully integrated was originally set for November 17, but SpaceX delayed it by 24 hours to replace a grid fin actuator on the launch stack. The launch is currently scheduled to occur from the company’s Starbase site near Boca Chica, Texas.

SpaceX launched its first Starship on April 20, but the rocket was intentionally exploded after its stages failed to separate as planned. The 33 engines of the Super Heavy first stage carved a huge crater beneath its launch mount, which SpaceX spent months repairing and upgrading.

SpaceX has since installed a water deluge system beneath the launch pad to avoid creating another crater on this launch. Additionally there is now a hot-staging technique for stage separation, in which the upper Starship stage begins firing its engines before separating from the Super Heavy.

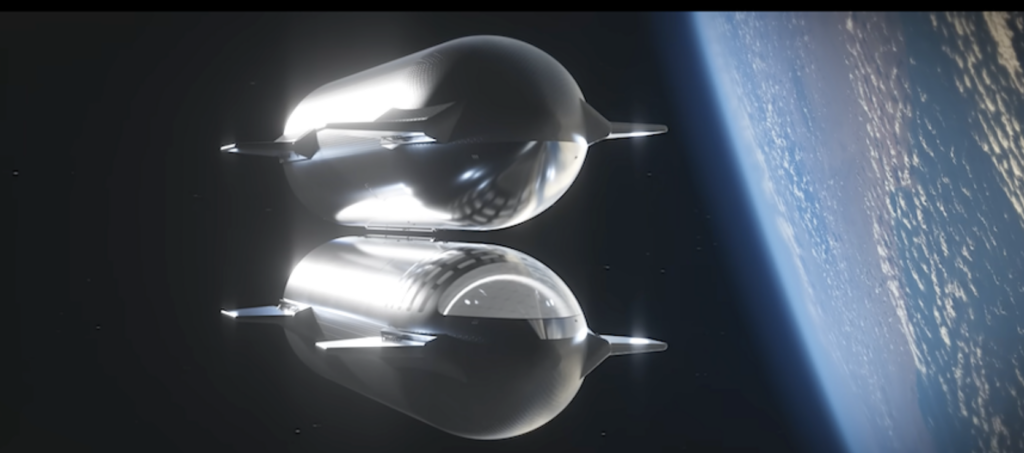

“This is another chance to put Starship in a true flight environment, maximizing how much we learn,” SpaceX wrote in a November 16 update on X, formerly known as Twitter. “This is another chance to put Starship in a true flight environment, maximizing how much we learn. Rapid iterative development is essential as we work to build a fully reusable launch system capable of carrying satellites, payloads, crew, and cargo to a variety of orbits and Earth, lunar, and Martian landing sites.”

The second flight test of a fully integrated Starship is set to launch Friday, November 17. A two-hour launch window opens at 7:00 a.m. CT.

A live webcast of the flight test will begin about 35 minutes before liftoff, which you can watch on X @SpaceX. Be aware of possible updates as is the case with all developmental testing, the schedule is dynamic and likely to change.

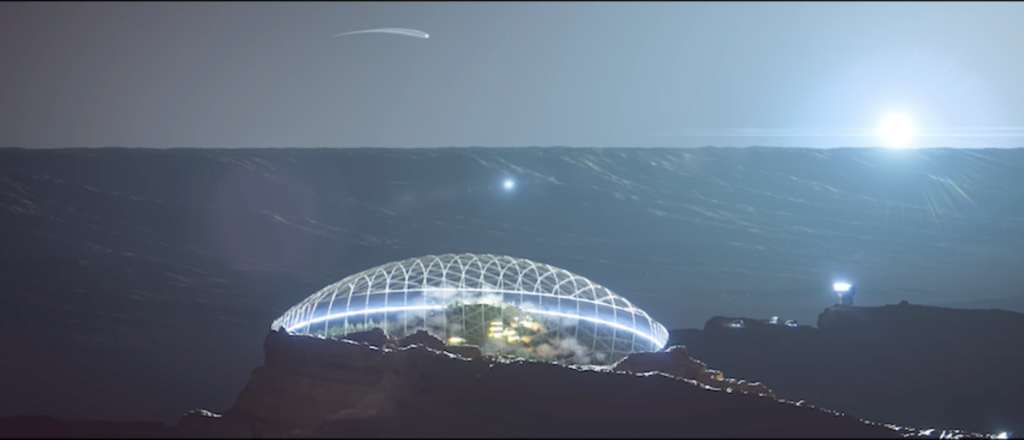

As the most powerful launch system ever developed, Starship will be able to carry up to 100 people on long-duration, interplanetary flights. Starship will also help enable satellite delivery, the development of a Moon base, and point-to-point transport on Earth.

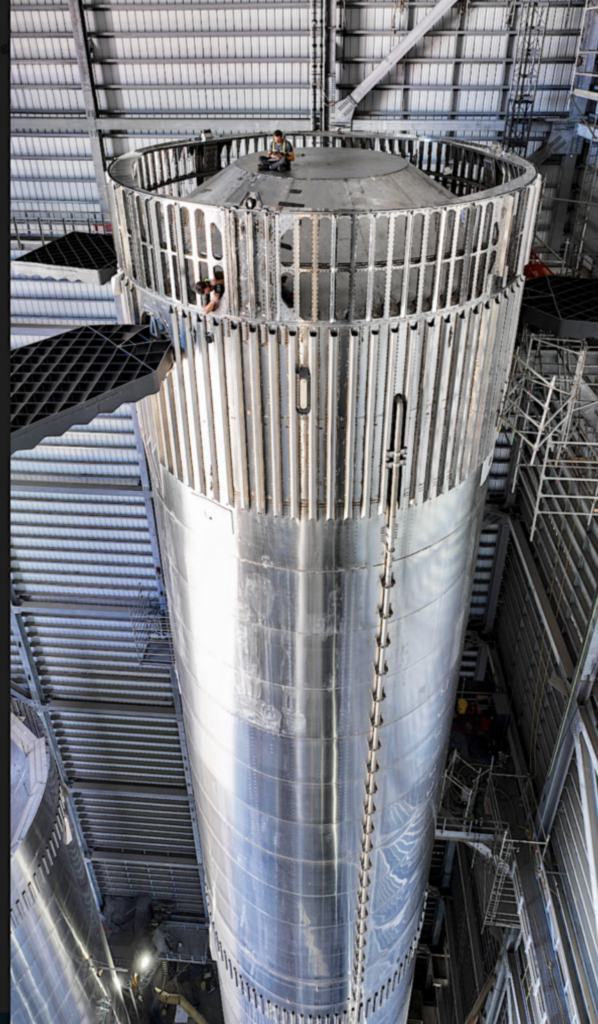

Starship’s first flight test provided numerous lessons learned that directly contributed to several upgrades to both the vehicle and ground infrastructure to improve the probability of success on future flights. The second flight test will debut a hot-stage separation system and a new electronic Thrust Vector Control (TVC) system for Super Heavy Raptor engines, in addition to reinforcements to the pad foundation and a water-cooled steel flame deflector, among many other enhancements.

UPGRADES AHEAD OF STARSHIP’S SECOND FLIGHT TEST

The first flight test of a fully integrated Starship and Super Heavy was a critical step in advancing the capabilities of the most powerful launch system ever developed. Starship’s first flight test provided numerous lessons learned that are directly contributing to several upgrades being made to both the vehicle and ground infrastructure to improve the probability of success on future Starship flights. This rapid iterative development approach has been the basis for all of SpaceX’s major innovative advancements, including Falcon, Dragon, and Starlink. SpaceX has led the investigation efforts following the flight with oversight from the FAA and participation from NASA and the National Transportation and Safety Board.

Starship and Super Heavy successfully lifted off for the first time on April 20, 2023 at 8:33 a.m. CT (13:33:09 UTC) from the orbital launch pad at Starbase in Texas. Starship climbed to a maximum altitude of ~39 km (24 mi) over the Gulf of Mexico. During ascent, the vehicle sustained fires from leaking propellant in the aft end of the Super Heavy booster, which eventually severed connection with the vehicle’s primary flight computer. This led to a loss of communications to the majority of booster engines and, ultimately, control of the vehicle. SpaceX has since implemented leak mitigations and improved testing on both engine and booster hardware. As an additional corrective action, SpaceX has significantly expanded Super Heavy’s pre-existing fire suppression system in order to mitigate against future engine bay fires.

The Autonomous Flight Safety System (AFSS) automatically issued a destruct command, which fired all detonators as expected, after the vehicle deviated from the expected trajectory, lost altitude and began to tumble. After an unexpected delay following AFSS activation, Starship ultimately broke up 237.474 seconds after engine ignition. SpaceX has enhanced and requalified the AFSS to improve system reliability.

SpaceX is also implementing a full suite of system performance upgrades unrelated to any issues observed during the first flight test. For example, SpaceX has built and tested a hot-stage separation system, in which Starship’s second stage engines will ignite to push the ship away from the booster. Additionally, SpaceX has engineered a new electronic Thrust Vector Control (TVC) system for Super Heavy Raptor engines. Using fully electric motors, the new system has fewer potential points of failure and is significantly more energy efficient than traditional hydraulic systems.

SpaceX also made significant upgrades to the orbital launch mount and pad system in order to prevent a recurrence of the pad foundation failure observed during the first flight test. These upgrades include significant reinforcements to the pad foundation and the addition of a flame deflector, which SpaceX has successfully tested multiple times.

Testing development flight hardware in a flight environment is what enables our teams to quickly learn and execute design changes and hardware upgrades to improve the probability of success in the future. We learned a tremendous amount about the vehicle and ground systems during Starship’s first flight test. Recursive improvement is essential as we work to build a fully reusable launch system capable of carrying satellites, payloads, crew, and cargo to a variety of orbits and Earth, lunar, or Martian landing sites.

This rapid iterative development approach has been the basis for all of SpaceX’s major innovative advancements, including Falcon, Dragon, and Starlink. Recursive improvement is essential as we work to build a fully reusable transportation system capable of carrying both crew and cargo to Earth orbit, help humanity return to the Moon, and ultimately travel to Mars and beyond.