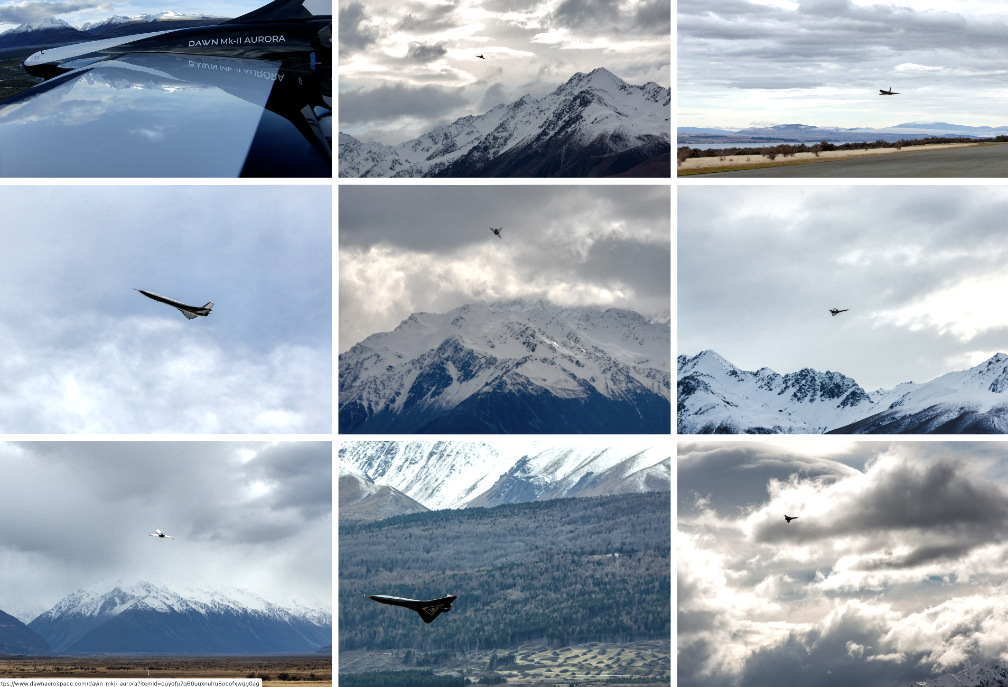

Dawn Aerospace has completed 48 flights of their spaceplane technology demonstrator, the Mk-II Aurora, over the last 13 months to complete Phase One testing of the vehicle using surrogate jet engines — tests of the vehicle under rocket power are expected before the end of the year.

Phase One demonstrated all non-rocket systems on the spaceplane, such as low speed aerodynamic performance, pilot controllability, reliability and general airworthiness. The spaceplane was flown as fast as 200 knots (370 km/h) and 9,000ft altitude, although high speed and altitude were not primary goals.

In Phase two of the test program, the Mk-II Aurora will be fitted with a rocket motor that will allow for flights to over 100 km. altitude and 3,500 km/h. If achieved, it would be the first vehicle to ever to reach space twice in a day – “a Wright Brothers moment for reusable spaceflight” said Stefan Powell, CEO.

The Mk-II is intended to prove the core technology needed for a fully and rapidly reusable, first stage booster. Once the Mk-II Aurora is proven under rocket power, a much larger Mk-III vehicle will be built, with the capability to deliver a 250 kg. satellite into orbit using a second stage released at high altitude.

“Rapid reusability is the key to cost effective spaceflight,” said CEO Stefan Powell, “Operating under aviation law, and with a vehicle that is an aircraft first, and a rocket second, allows us to unlock the powers of fleet economics. We can replace an entire rocket factory with a few aircraft that operate daily.”

Phase One test flights were conducted under aircraft certification, specifically Civil Aviation Authority Part 102. As of September, all test goals were achieved, including a “pseudo-rocket powered flight” where the aircraft was flown at full thrust and a high pitch angle to moderate altitude before having the engines intentionally set to idle, mimicking main engine cut-off.

Thereafter, the aircraft was brought into land using only maneuvers and air brakes to control airspeed, similar to what will be done after re-entry from high altitude. Glide landings were repeated several times as part of the team’s final flight training before the spaceplane will be fitted with a rocket motor. In addition to substantial simulator testing, these tested served as confirmation that the team is ready for rocket powered flight. Phase one also demonstrated key operational aspects of the spaceplane, including rapid reusability, up to four flights in a day, and flights under aviation law.

The Mk-II rocket engine is a liquid propellant rocket motor, developed by the company, and uses the non-cryogenic fuels hydrogen peroxide and kerosene which are aircraft storable, unlike typical rocket fuels such as liquid oxygen. The engine, which is in the final stages of qualification, is designed for rapid restarts without the replacement of igniters or other maintenance. Test flights of the Mk-II under rocket power are anticipated before the end of the year.

“This test phase has shown that the basic design is extremely capable, but above all, safe. It was also a key step to show that the team is ready to take on the challenge of rocket-powered flight,” CFO and Mk-II Chief Engineer, James Powell, said. “As a clean sheet design, there were naturally many aspects that were unproven. The combination of simulation and real testing is critical in achieving a safe and successful campaign. We are on the path to revolutionizing how we access space. The ability to rapidly reuse a launch vehicle reduces costs by 90 per cent, hence it has always been the holy grail of affordable, frequent space flight.“