Mitsubishi Electric Corporation (TOKYO: 6503) has developed an on-orbit, additive-manufacturing technology that uses photosensitive resin and solar ultraviolet light for the 3D printing of satellite antennas in the vacuum of outer space.

The novel technology makes use of a newly developed liquid resin that was custom formulated for stability in vacuum. The resin enables structures to be fabricated in space using a low-power process that uses the sun’s ultraviolet rays for photopolymerization.

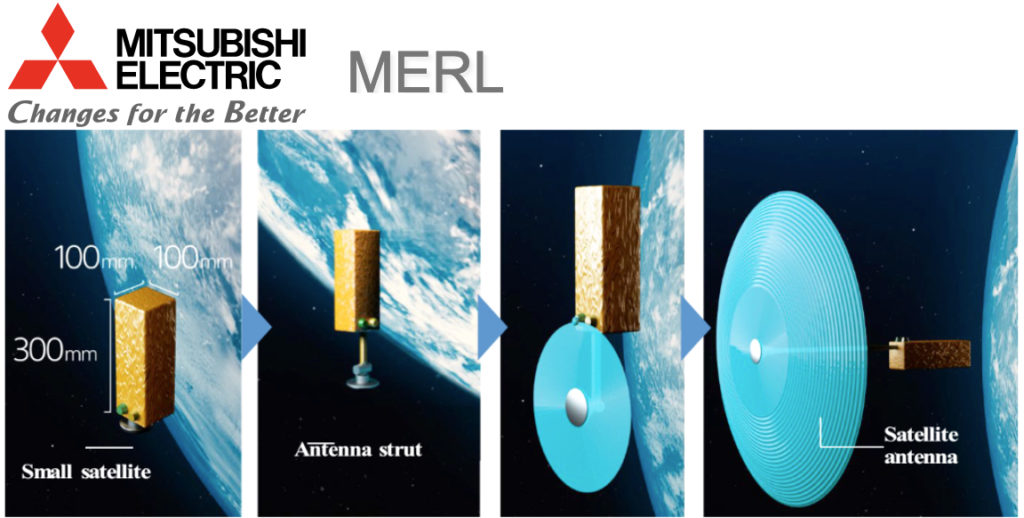

The technology specifically addresses the challenge of equipping small, inexpensive spacecraft buses with large structures, such as high-gain antenna reflectors, and enables on- orbit fabrication of structures that greatly exceed the dimensions of launch vehicle fairings. Resin-based, on-orbit manufacturing is expected to enable spacecraft structures to be made thinner and lighter than conventional designs, which must survive the stresses of launch and orbital insertion, thereby reducing both total satellite weight and launch costs.

Spacecraft antenna designs are challenging, due to their conflicting requirements for high gain, wide bandwidth and low weight. High gain and wide bandwidth necessarily require a large aperture, but economical orbital deployment conventionally dictates that designs be lightweight and small enough to fit or fold inside a launch vehicle or satellite deployment mechanism. Mitsubishi Electric’s innovative approach—resin-based on-orbit manufacturing—efficiently realizes high-gain, wide-bandwidth, large-aperture antennas deployed from a lightweight, vibration-resistant launch package. By developing a 3D printer that extrudes a custom ultraviolet-curable resin formulated for vacuum, resin-based low-power freeform (without requiring auxiliary support structures) additive-manufacturing in space has now become possible.

Features

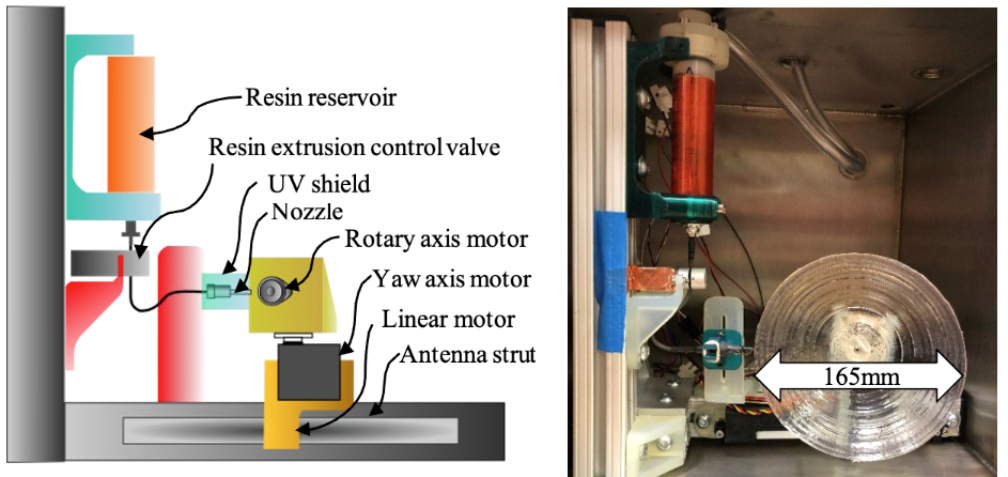

1) 3D printer for the freeform fabrication of antennas in vacuum

— The 3D printer shares the antenna’s struts and angle-adjustment motors.

— Antenna size is not limited by the size of the fairing of the launch vehicle or the size of the satellite bus.

— On-orbit manufacturing eliminates the need for an antenna structure that can withstand vibrations and shocks during launch, which is required for conventional antenn areflectors, making it possible to reduce the weight and thickness of antenna reflectors, thereby contributing to the reduction of satellite weight and launch costs.

— Assuming the use of a 3U cubessat (100 x 100 x 300 mm) specification, an antenna reflector with a diameter of 165 mm, which is larger than the size of the cubesat bus, was fabricated in air and a gain of 23.5 dB was confirmed in the Ku-band (13.5 GHz).

2) World’s first** (as of May 17, 2022, according to the company’s research) photosensitive resin with stability suitable for extruding and curing in vacuum

— Commercial photosensitive resins have low molecular weight, high vapor pressure, and are not suitable for vacuum applications, where they boil and prematurely polymerize. The newly developed ultraviolet-curing resin uses a high-molecular-weight, low-vapor-pressure oligomer base blended with a vacuum stable plasticizer based on a non-volatile, polyphenyl ether to achieve a viscosity suitable for extrusion in vacuum.

— As most polymerization inhibitors require atmospheric oxygen as a co-factor to prevent premature polymerization and do not function in vacuum, the new resin formulation uses inhibitors that do not depend on the presence of oxygen and have near-zero volatility.

— When exposed to ultraviolet light, the resin polymerizes by crosslinking into a solid that is heat-resistant to at least 400°C, which is beyond the maximum temperature experienced on-orbit.

— The use of sunlight for polymerization and curing eliminates the need for a separate ultraviolet light source, enabling manufacturing with low power consumption.

Future Developments

Mitsubishi Electric’s resin-based, on-orbit manufacturing enables smallsats to achieve large-satellite capabilities, which reduces launch costs and allows for satellite technology to be used more than ever in applications such as communication and Earth Observation (EO). These extended capabilities are expected to enable more timely provision of satellite imagery and observation data that meet the varied needs of individuals and organizations.