Maxar has successfully completed the spacecraft Accommodation Critical Design Review (CDR) for the On-Orbit Servicing, Assembly and Manufacturing (OSAM-1) mission, a major milestone that paves the way for the team to complete the final mechanical build of the spacecraft.

OSAM-1 will refuel a satellite in LEO not designed to be serviced. In doing so, the mission will validate many of the essential tools, techniques and technologies to enable future science and space exploration missions, bolster national security and spur development of innovative commercial platforms and businesses. NASA’s Space Technology Mission Directorate funds and manages the technology demonstration mission.

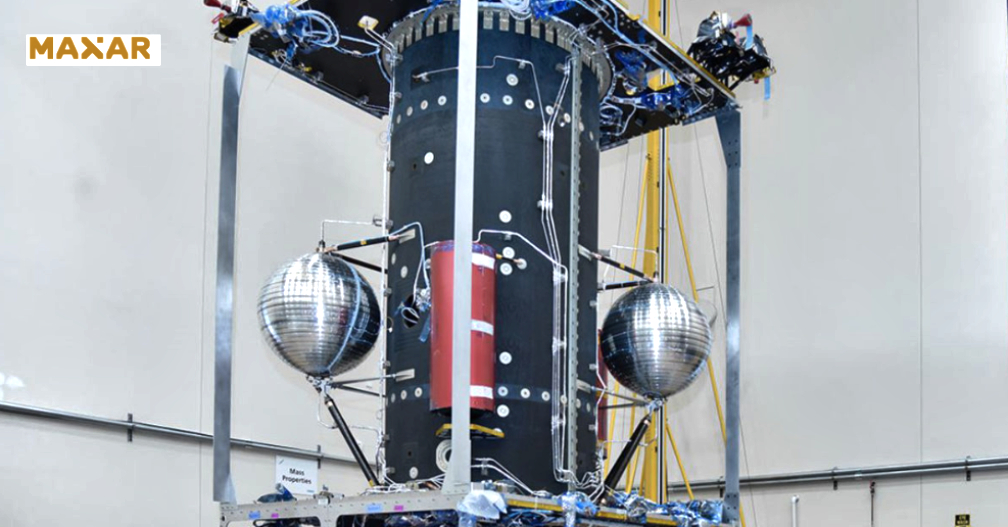

The OSAM-1 spacecraft bus is currently under development at the Maxar facility in Palo Alto, California. In the above image, OSAM-1’s propulsion system is shown near completion on an alignment dock.

Inside the main cylinder are two large bipropellant tanks that will provide the fuel and oxidizer propellants to the thrusters, allowing the OSAM-1 spacecraft to maneuver in orbit. Small thrusters at both the upper and lower decks of the spacecraft will allow the spacecraft to maneuver with six degrees of freedom. That means OSAM-1 will have a unique three-axis translational maneuver capability, including the ability to execute “back away” maneuvers. This is an important safety feature, as the OSAM-1 spacecraft will approach and rendezvous with an existing government-owned satellite in orbit and refuel it. The two large silver spheres will be filled with monopropellant fuel to service the existing satellite. These spherical tanks are spare Auxiliary Power Unit tanks from the Space Shuttle program.

Maxar is working toward completing the main body assembly of OSAM-1 in summer 2021, followed by about a year of Reference Performance Testing on all subsystems prior to shipping the spacecraft to NASA’s Goddard Spaceflight Center in Greenbelt, Maryland.

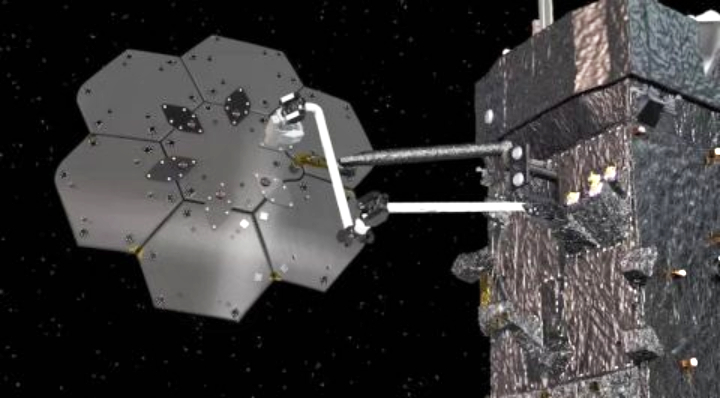

After arrival at Goddard, the Maxar and NASA teams will complete the installation of the Maxar-built SPIDER robotic arm and the Tethers Unlimited-built MakerSat to the spacecraft bus. (* Tethers Unlimited is currently preparing a flight experiment called “MakerSat” that will demo in-space manufacture of very large composite structures. Essentially, MakerSat will manufacture carbon-fiber 2-by-4’s that, in the future, can be used to assemble very large structures to support antennas, solar sails, solar arrays, or even habitats.)The final step will be to integrate the NASA-provided robotic servicing payload onto the spacecraft bus, which will complete the flight build configuration of OSAM-1.

OSAM-1’s design is based on Maxar’s decades-proven 1300-class spacecraft platform, which offers a powerful mix of reliability, flexibility and cost-effectiveness for the mission. Maxar is leveraging also its 1300-class spacecraft platform for the Power and Propulsion Element of NASA’s Artemis program and NASA’s Psyche mission destined for a metal-rich asteroid.

NASA’s TEMPO science payload is also being flown as a hosted payload on a 1300-based commercial satellite. As the world’s most trusted commercial spacecraft platform, there are more than 90 1300-class spacecraft on orbit today.

Maxar is building three robotic arms for the OSAM-1 mission, two of which will be used for the refueling mission. The other robotic arm, SPIDER, will be used to demonstrate groundbreaking and fundamental technologies for sustainable space exploration. This includes in-space assembly of large-scale segmented antenna reflectors and supporting MakerSat’s manufacturing of a composite beam while on orbit.

Maxar has teamed with the West Virginia Robotic Technology Center to provide independent verification of SPIDER’s capabilities through multiple performance studies.