Exotrail reports the full success of the first-ever cubesat mission equipped with Hall-effect electric propulsion technology. Through an In-Orbit Demonstration mission launched to LEO on November 7, 2020, onboard a PSLV rocket, Exotrail nominally ignited its ExoMG™ Hall-effect electric propulsion system on the first attempt.

Smallsat constellations will now be able to quickly change their orbit once in space, giving new capabilities for satellite operators as well as more flexibility in their launch strategy, dramatic performance increases, collision avoidance and safe de-orbiting to prevent space pollution.

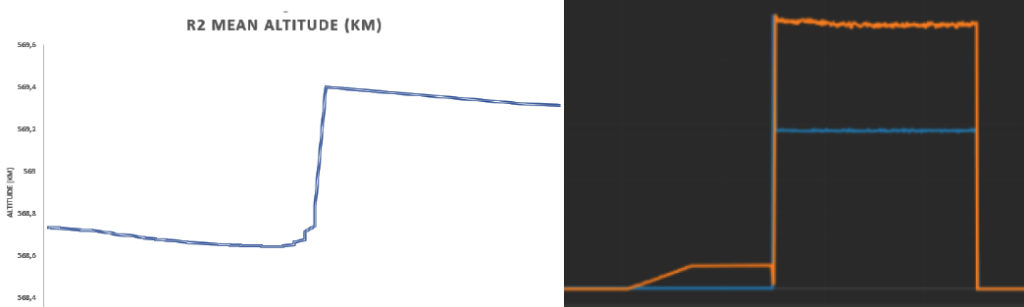

(Credits: Space-Track.org)

Right: Thruster parameters during ignition in space (voltage and current) which confirm the nominal behavior of the testing (Credits: Exotrail)

Right: In space seconds after launch. (Credits: NanoAvionics, ISRO)

This success marks a major milestone for Exotrail in the company’s journey to become a space mobility leader, allowing the company to validate in space its product building blocks dedicated to satellites ranging from 10 to 250 kilograms.

ExoMG™ electric propulsion system is being operated with ExoOPS™, Exotrail’s operation software, simultaneously validating not one but two products of the company. This mission opens up a new era for the space industry: ExoMG™ is the first ever Hall-effect thruster operating on a sub-100 kg spacecraft. This success is strengthened by the extremely short development timeframe, with less than a year from design to delivery. The pandemic and launch delays also caused one year of storage at the launch operator facilities without specific monitoring. This shows the extreme reliability of ExoMG™ product.

After concluding a first demonstration phase with an altitude change in December 2020, Exotrail will continue demonstrating additional capabilities of its solutions in 2021. Exotrail has already delivered ExoOPS™ software suite to various clients around the world as well as several flight-grade ExoMG™ propulsion systems to customers on two continents. Several additional propulsion systems are in production for institutional and commercial clients, such as ESA and AAC Clyde Space.

At least four mission shall fly with Exotrail product onboard in 2021 and more ExoOPS™ software deployed with new customers to be announced soon.

Hall-effect thrusters are mainly used on large satellites due to their superior efficiency compared to other electric propulsion technologies. Legacy systems, however, are the size of a fridge and require kilowatts of power. Exotrail’s smallsat thruster runs on 50 watts of power and is equivalent in volume to 2 liters of soda. On top of designing and packing world-leading innovations at the thruster level, Exotrail’s team managed the integration of the propulsion system inside the 10 kilograms spacecraft.

Another key element of innovation comes from the use of ExoOPS™, Exotrail’s constellation operation software. The software has been instrumental to the realization of the mission. Integrated seamlessly within NanoAvionics’ space infrastructure, ExoOPS™ allows to command the attitude and propulsion system of the spacecraft and to perform advanced and automatic maneuvers. ExoOPS™ can also provide capabilities such as orbit determination and propagation, ground station visibility planning or constellation management. The next steps will be dedicated to advanced maneuvering capabilities to demonstrate altitude change, inclination correction, station-keeping, anomaly and plane change, collision avoidance and de-orbit capability.

“Everything worked better than anticipated. Some customers already told us we made history with that mission! Beyond these nice words – a true recognition of the hard work performed by all Exotrail team – it makes our strategy a reality: to operate a high-thrust and flexible electric propulsion system seamlessly with our operations software. We are beyond thrilled!” reported David Henri, Co-Founder and CEO of Exotrail. “We also want to claim the success of our mission showing tangible proofs based on real data. We are happy to report data from our ExoOPS™ software, but also external tracking elements.”

“We have confirmed nominal operations of our electronics, our fluidics and our thruster head sub-systems. We are now gathering a lot of data to verify the impact of the space environment on our performances and operations. For now, we are very happy with the results as we exceeded our mission objectives.” said Jean-Luc Maria, Co-founder and CTO of Exotrail.

“We confirm that this testing was successful with nominal results at platform level and an altitude change. It has been great working with Exotrail on this journey,” said Arnoldas Pečiukevičius, Head of Systems Engineering at NanoAvionics, the smallsat manufacturing company who built the satellite in which ExoMG™ is included. “I would like to congratulate the whole Exotrail team on achieving this huge goal. Now that Exotrail’s technologies are space-proven, mobility solutions will be instrumental for a safer space.”